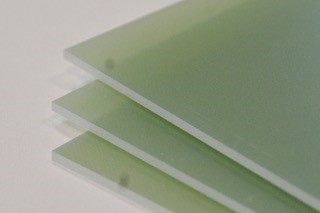

Test Fixturing Laminates

PCB and PCBA e-test fixture component laminates often require special properties to ensure surface evenness, flatness, surface resistivity, high flexural strength, and RoHS compliance. Our component laminates are all certified to industry standards at a minimum and cut to precise dimensions per your custom specification accurate to +/-0.0070″.

FR4/G10 Probe Plates : 0.125″, 0.187″, 0.200″, 0.250″, 0.375″, 0.500″ Natural color. Additional grinding services available to achieve tighter tolerances on flatness or evenness. Standard stock certified to IPC4101D/21 and MIL I 24768/27 thickness tolerances.

ESD G10: 0.200″, 0.300″ 0.375″ (single-sided, matte finish, surface resistance certified 10 6 to 1011 ohms/sf)

High Flexural Performance: Larger surface area designs allow no bow or flex and require the specialized properties of our GL-850HF material. Available in all thicknesses as our standard G10, this high-performing material guarantees robust rigidity even when sparsely supported and highly populated.